Introduction

A rigger is a person that specializes in the lifting and moving of extremely large or heavy objects. There is no place for shortcuts when performing this important job. Riggers must use approved rigging hardware and know how to apply standards that apply to each situation. They need to be able to select proper hardware, know how to calculate the weight of an object, and determine the center of gravity of the load. This course covers all the fundamentals, including necessary training and qualifications, hand signals, general standards, rigging components, rigging hook-ups, inspection and controls.

Course Content

- Course Introduction (Course Objective, OSHA 1994 and FMA 1967)

- Safety and Accidents (Understanding of Safety, Preparation of Operator, Safety Equipment, Accidents - Aspects and Implications)

- Types of Cranes (Structure and Built of Cranes)

- Crane Operation - Long Travel, Cross Travel and Hoisting& Rigging)

- Crane System Introduction (Ensuring Safety when Handling of Crane, Brake System, Limit Switch, Emergency Stop, Wire Ropes and Types of Slings, Crane and Slings Inspection)

- Machinery Handling (Preventive Maintenance Procedure, Servicing, Greasing)

- Video Session of Cranes (Safety Procedures for Self and Company Assets, Root Causes of Accidents, Proper Methods of Handling Crane)

- Post-Theory Test

- Practical Sessions

- Practical Test

Target Group:

- Health & Safety Committee Members

- Managers, Engineers, Supervisors, workers

- All Crane, Hoist and slinging handlers.

Methodology

- Case studies

- Group Presentation.

- Identify Hazards.

- Crane handlers commitments

- Proactive accident prevention methods.

- Real Video Crane accident presentation.

Certification:

- Certificates of Attendance in “Hoist and Rigging ” are awarded to participants on successful completion of course of 2days

- “Competent Crane Handler” (CCH) Card will be given to those Pass the Assessment

Course Contents

Day 1

- Legal requirements for Occupational Safety and Health Act 1994

- Factory and Machinery Act 1967 Crane Test and Certification requirement.

- Type of Crane and Operation, Hoist and Rigging Methods.

- Responsibility of employer and Employee of Crane Safety

- Identify Crane Hazards and Preventive Measure

- Crane hoist accessories i.e. shackles, Sling, eye bolts.

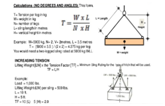

- How to calculate sling weight.

- Group Presentation.

- How to change unsafe Act to Save Condition

Day 2

- Correct method of using overhead crane Hoist, Cross bar, Chain, Sling

- Safety Compliance Hazard Audit- Practical

- Group assignment to Identify Hazard - PracticalGroup Workshop and discussion on Hazards

- Individual crane assessment(Practical Test)

- Test result and certificate presentation – Q&A close

Safety is not a gadget but a state of mind.

It takes leadership to improve safety.

The safety of the people shall be the highest law.